How Galvanizing Fights off Corrosion

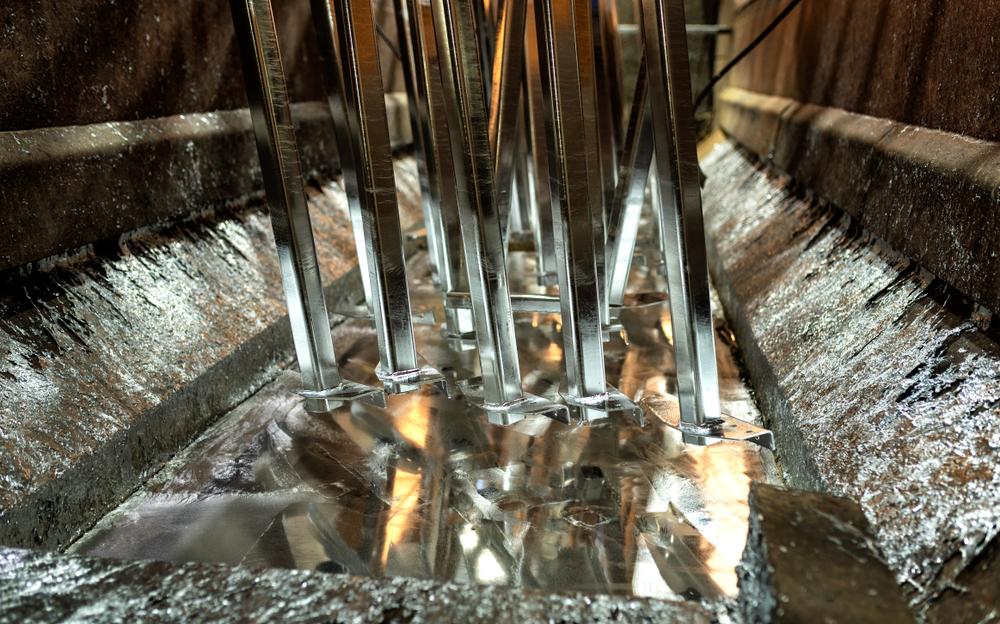

With corrosion all around us, you really can’t have enough preventative measures against warding it off. Damages from corrosion are costly, unsafe, and frustrating. Thankfully processes like galvanization are here to prevent the damages caused by corrosion. Galvanizing is a process whose sole intention is to ward off corrosion and prevent rust from occurring on equipment. Discovered in 1780 by Italian-born Luigi Galvani, this phenomenon presents a fascinating method of protection from corrosion. Zinc is the main property within the galvanizing process. The process of galvanization is simple yet extremely effective. First, iron or steel equipment is coated with a layer of zinc. When this layer is applied, the process of galvanization takes place. Oxygen and water make their way towards the material yet are prevented from reaching the metal underneath the zinc coating. This prevention leads to zinc sacrificing itself in the process. Known as a sacrificial material, the zinc essentially corrodes before the iron or metal does, giving itself up so that the surface stays pure and free from corrosion. Galvanisation represents one of many tried and true methods of warding off corrosion.

Safeguarding your equipment from corrosion starts with making sure your equipment is in shape. Regular inspections can keep your investments from becoming the victim of localized corrosion. Is maintaining your equipment imperative to you? Give us a call today at 432-606-4093 and keep your equipment free from the dangers of corrosion. We will give your equipment the inspection it needs with the estimate you deserve. By providing services designed to prevent corrosion, we help clients avoid costly steel repair or replacement. Visit our website at www.spearindustrial.com or call us today at 432-606-4093 and let us help you protect your investment.